Managing warehouse inventory efficiently requires making strategic decisions every day: product rotation, order fulfillment speed, and the level of quality guaranteed to the end customer. It is always a matter of balance between operational rules, physical constraints, and business objectives.

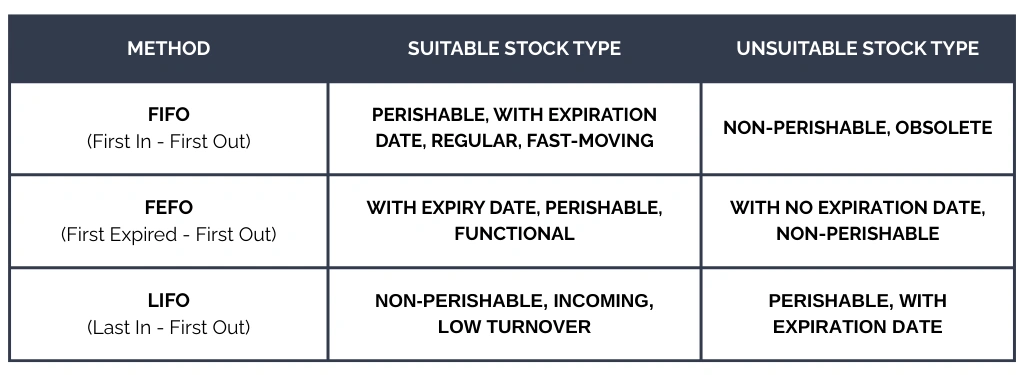

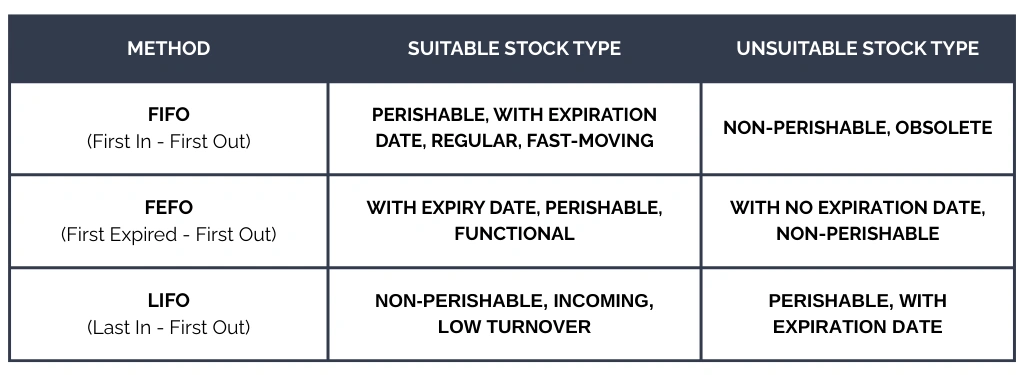

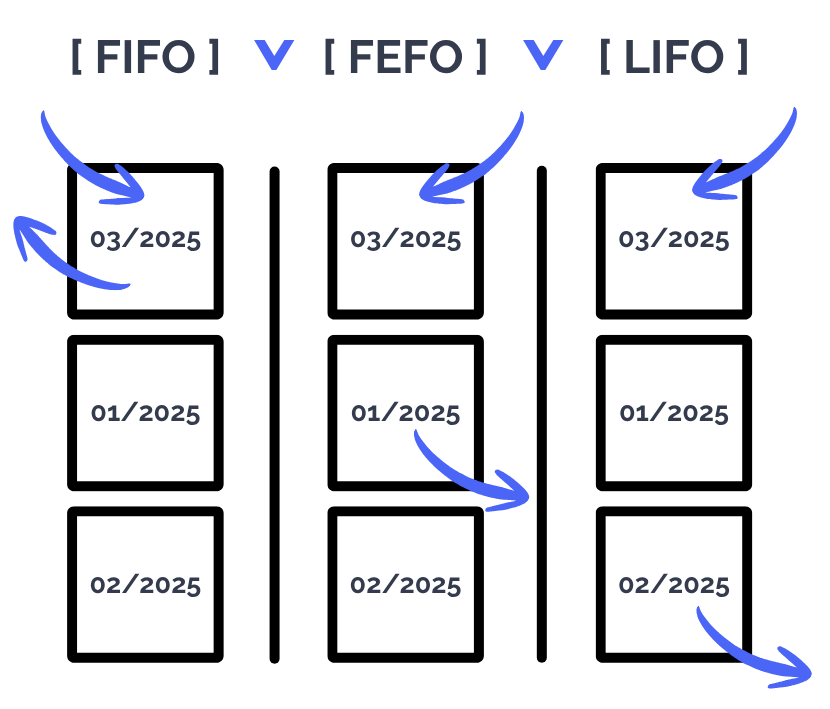

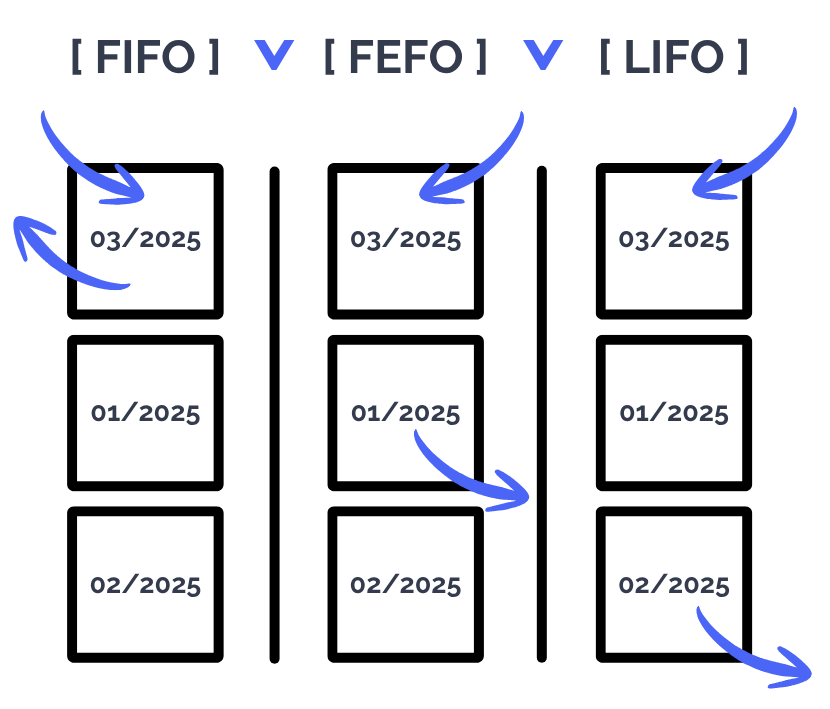

To maintain this balance, many companies rely on established inventory management methods: FIFO (First In, First Out), FEFO (First Expired, First Out), and LIFO (Last In, First Out). Each of these approaches has its own characteristics, advantages, and ideal use cases. The key to using them effectively lies in proper configuration, based on the type of product and the warehouse flow.

To explore the topic in depth, we spoke with Riccardo De Pra, Software Developer at Stesi, who guided us through the principles, benefits, and real-world applications of these three inventory management logics.

What Are Warehouse and Inventory Management Methods?

In a warehouse, deciding which product should be shipped first is never a random choice. It depends on the type of goods, their destination, how storage space is organized, and the company’s operational priorities.

To manage all of this in a structured and efficient way, several inventory management logics exist, among the most well-known are FIFO, FEFO, and LIFO.

Each of these logics is based on a different rule (receipt date, expiration date, or most recent arrival), but they all share the same objective: ensuring proper stock rotation, minimizing waste, and keeping operations running smoothly.

In practice, however, these logics are not rigid rules. “They are configurable tools that adapt to the customer’s specific needs,” explains Riccardo. “They can be assigned by product category, warehouse zone, or even combined”. This flexibility is precisely what makes their use truly strategic.

What Role Does a WMS Play in Implementing These Logics?

A Warehouse Management System (WMS) enables all of this to be managed automatically. The system enforces the defined rules, removing the need for operators to make discretionary decisions case by case.

“The goal is to remove this discretionary burden from the operator” Riccardo explains. “The WMS software knows every detail of the warehouse, from inventory levels to storage locations and shipment history, allowing it to optimize picking operations, increase throughput, and significantly improve overall efficiency”.

FIFO – First In, First Out

The FIFO method is based on a simple yet effective principle: the first pallet to enter the warehouse is also the first to leave. It is a chronological approach that respects the order of receipt and ensures predictable, orderly stock rotation.

This logic is particularly suitable for environments where products have a limited shelf life and cannot remain in storage for extended periods.

Pros and Cons of the FIFO Method

One of FIFO’s main strengths is its operational clarity. Defining that the first pallet received must also be the first shipped creates a structured flow that is easy to understand and follow, both in warehouse movements and in operators’ daily activities.

But the most interesting aspect is traceability. “With FIFO, you always have a clear view of what entered the warehouse, when it entered, and when it should leave” Riccardo explains. “This allows you to monitor the entire lifecycle of each batch”. This is particularly valuable in terms of control and safety when handling perishable or regulated products.

However, FIFO requires specific conditions to be implemented effectively. Not all warehouse layouts are suitable. Limited space or racking systems that do not allow easy access to older pallets can make FIFO harder to apply and negatively impact operational speed. “FIFO works best in environments designed to support it,” Riccardo notes, “with orderly warehouses, flow-through racking, or storage lanes organized by receipt date”.

When FIFO Makes Sense

The benefits of FIFO make it particularly suitable for industries such as Food & Beverage, Pharmaceuticals, and Electronics, where time is a critical factor. In these sectors, ensuring that products move in the correct order helps preserve quality, comply with regulations, and reduce waste.

FEFO – First Expired, First Out

The FEFO method is based on product expiration dates. Unlike FIFO, FEFO prioritizes shipping the batches that will expire first, regardless of when they were received.

This logic is designed for optimal management of perishable goods or any items with a defined shelf life. What matters is not when the product arrived, but how much usable time remains.

Pros and Cons of the FEFO Method

The main advantage of FEFO is its precision in managing perishable inventory. Prioritizing shipments based on expiration dates minimizes waste, reduces returns, and ensures that customers always receive products that are compliant, usable, and of high quality.

FEFO is especially useful when storage times vary or when, due to production or logistical reasons, a more recently received batch must be shipped earlier than older ones.

That being said, FEFO requires strict prerequisites: expiration dates must be fully traceable, and operators must be able to identify and validate batches at every stage. Without an automated system managing the flow, the risk of human error increases, along with operational complexity.

When FEFO Makes Sense

FEFO is the ideal choice whenever inventory management must adhere to a clear principle: preventing products from expiring before distribution. This is why it is widely used in the Food, Pharmaceutical, and Cosmetics industries, where regulations are strict and traceability is mandatory.

Among Stesi’s customers that have implemented FEFO are companies such as Molino Pordenone and Alce Nero. The former specializes in professional-grade flour production, while the latter is known for its wide range of packaged food products. In both cases, ensuring product freshness was critical, leading to the implementation of FEFO logic in the WMS, along with an additional rule: preventing the shipment of batches with an earlier expiration date than those previously delivered to the same customer.

LIFO – Last In, First Out

The LIFO method dictates that the most recently received pallet is the first to be shipped. While this approach may seem counterintuitive compared to traditional rotation methods, it is perfectly suited to certain operational contexts.

This is typically the case for warehouses handling non-perishable materials or products that do not require strict chronological rotation. Prioritizing access to the most recent pallets can optimize space utilization, reduce picking times, and simplify material handling.

Pros and Cons of the LIFO Logic

LIFO’s main advantage lies in its operational simplicity. In warehouses where racking is accessible only from the front, retrieving the most recent pallet is often the fastest option. This reduces unnecessary movements, speeds up picking, and optimizes space usage, especially in high-bay or vertical storage systems.

“It’s a very practical logic in warehouses where speed is the primary objective.” Riccardo explains. “It avoids unnecessary pallet handling and keeps operations fluid.”

On the downside, LIFO logic does not ensure orderly stock rotation. As a result, it is unsuitable for perishable products or items that require close monitoring of receipt dates. Over time, some pallets may remain at the back of the racking for too long, increasing the risk of obsolescence or quality degradation.

When LIFO Makes Sense

LIFO is effective when managing non-perishable materials or high-turnover goods, such as industrial raw materials, metal components, packaging materials, or spare parts, contexts where speed takes priority over chronological tracking.

It is therefore commonly adopted in warehouses handling large volumes where fast picking is essential and expiration constraints are not an issue.

Combining Different Inventory Logics

In daily operations, it is rare for a warehouse to rely on a single handling logic. Many companies manage diverse products, priorities, and flexible storage configurations. As a result, different inventory logics are often strategically combined based on product characteristics and warehouse layout. For example:

-

FEFO can be used for fresh goods to ensure expiration compliance;

-

FIFO for dry or packaged products to maintain orderly rotation;

-

LIFO for packaging, non-perishable raw materials, or low-priority items where operational speed is key.

“A well-configured WMS makes this complexity manageable.” Riccardo explains. “Each logic can be applied at the item, location, or process level, with the system guiding operators toward the correct choice.”

A concrete example comes from ALPLA, a Stesi customer specializing in plastic packaging manufacturing. In this case, the warehouse was configured to follow FIFO logic at a managerial level, ensuring batch traceability and proper stock rotation. At the same time, LIFO logic was applied operationally to streamline picking and improve efficiency.

The result is a so-called “near FIFO” logic, designed to accommodate physical constraints such as single-access storage lanes that require newer pallets to be moved first. The WMS enables this dual approach by identifying the correct storage lane, assigning the appropriate batch, and guiding operators efficiently, even when the physically picked pallet is not the oldest one in storage.

The outcome is an optimized flow, coherent rotation, and full control over the entire process.

FIFO, FEFO and LIFO: Choosing the Right Logic

Choosing between FIFO, FEFO, and LIFO is never a theoretical decision. It depends on the type of product, warehouse structure, and business objectives. What truly makes the difference is the ability to configure each logic correctly and integrate it into operational workflows.

A well-designed WMS allows different rules to be applied based on products, locations, or process stages, guiding operators in daily decisions and minimizing errors and inefficiencies.

If you want to understand how to best configure inventory handling logic in your warehouse, or learn more about silwa, Stesi’s WMS, get in touch with one of our experts. Together, we’ll find the solution that best fits your needs.

FAQ

Can I use multiple logics within the same warehouse?

Yes. This is a very common practice, especially in complex or multi-sector warehouses. A WMS allows different logics to be applied based on product type, warehouse area, or process stage.

Does the WMS choose the logic, or is it defined by the company?

The logic is always defined by the company during the configuration phase. The WMS software enforces these rules, ensuring operational consistency and supporting operators in picking and storage decisions.

Are there other methods besides FIFO, FEFO, and LIFO?

Yes. Less common approaches such as LEFO (Lowest Expiry, First Out) or HIFO (Highest In, First Out) exist and are used in specific contexts. Additionally, many companies define custom rules based on internal criteria such as destination, economic value, or customer priority.