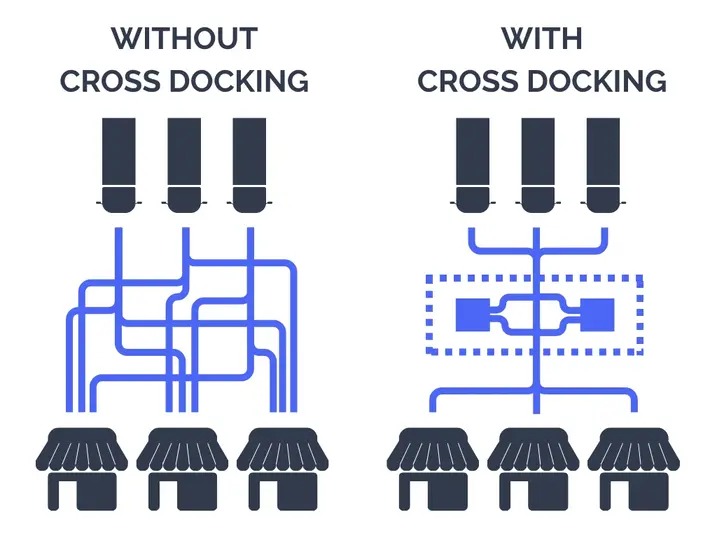

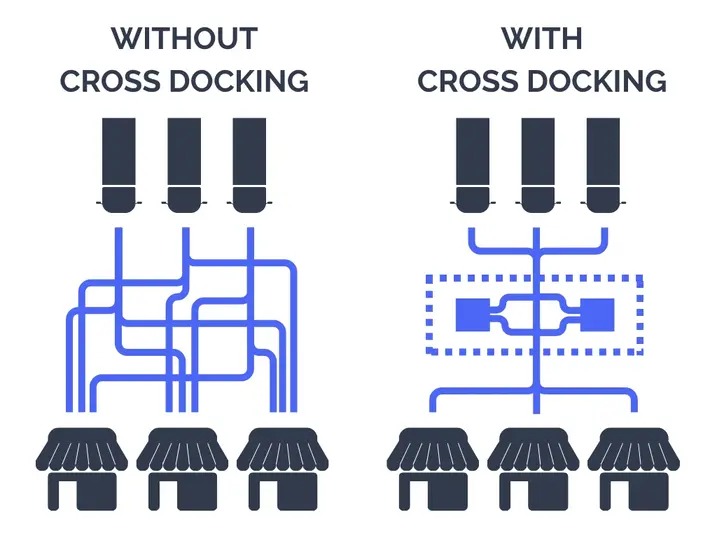

Logistics requirements are evolving rapidly. For many companies, reducing operational steps and shortening the time between inbound receiving and outbound shipping has become a concrete goal, often a necessary one to maintain smooth, controlled flows.

This is exactly where cross-docking logistics comes into play: an operational model designed to speed up goods handling, minimize storage, and optimize warehouse organization.

But what does cross docking actually imply, and under what conditions can it be applied effectively?

We discussed this with Nicola Da Re, Software Developer at Stesi, who guided us through operational principles, management models, and the digital tools required to adopt this approach in a structured way. First and foremost? WMS and TMS.

What Is Cross Docking? Definition and Meaning

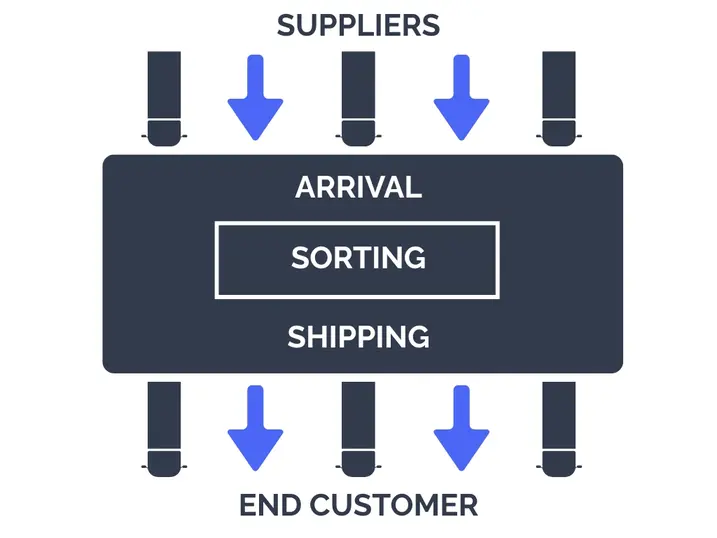

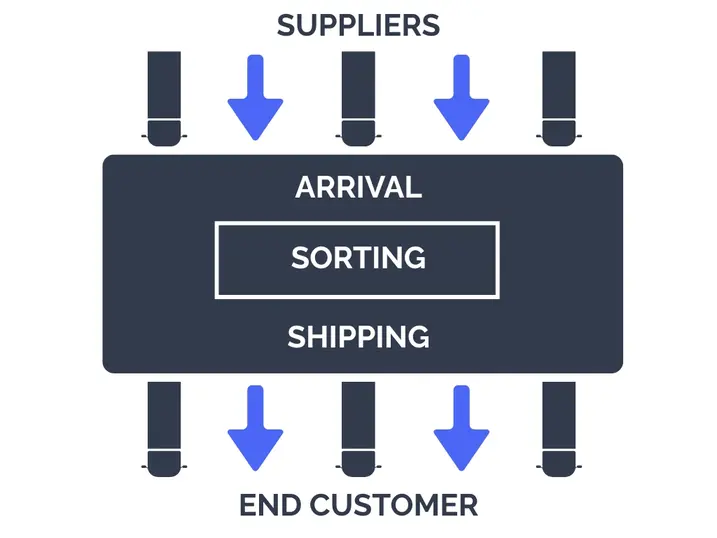

Cross docking is a logistics strategy that allows goods to be transferred directly from inbound receiving to outbound shipping, eliminating long-term storage in the warehouse. As Nicola explains, the goal is to speed up operations by “ensuring that goods are immediately routed to shipping, avoiding unnecessary steps such as put-away into storage locations and subsequent picking”.

Once goods arrive at the distribution center, they are immediately sorted by destination and loaded onto outbound vehicles for final delivery, without additional handling or idle time in the warehouse. “The success of this logistics strategy,” Nicola continues, “lies in its ability to reduce warehousing costs while also speeding up distribution and improving overall operational efficiency”.

Types of Cross Docking

Now that we have clarified what cross docking is, it is important to point out that several variants exist. “There are different operational types of cross docking,” Nicola explains, “and while there is no single best solution overall, each approach tends to fit specific business needs better”. Broadly speaking, cross docking can be divided into the following types:

- Pre-distribution cross docking: this is the simplest and fastest model, ideal when goods arrive already labeled and sorted by final destination. Once received, items are scanned and immediately routed to shipping, without being stored in the warehouse. This approach is particularly suitable for high-velocity products and continuous flows, where shipments are standardized. “In this case,” Nicola notes, “goods are received and shipped without any additional handling. It is the simplest model, but it is not suitable for customized orders that require picking activities”.

- Consolidation cross docking: this model requires more coordination, as goods are grouped together with other items to create optimized outbound shipments. Larger loading units are broken down and reorganized into shipments destined for multiple customers or locations. “It is no coincidence that this model works best for multi-customer or multi-product orders,” Nicola explains, “and is widely used in distribution and retail, where shipments often include products from different suppliers”. Although slower than pre-distribution cross docking, it offers greater flexibility, making it ideal for more complex orders.

- Hybrid cross docking: a combination of the two previous models, hybrid cross docking allows some goods to be shipped without modification, while others are broken down and reassembled into more precise shipments. This approach is ideal for seasonal demand or situations where demand fluctuates and is widely used in e-commerce, where speed and flexibility are critical. As Nicola observes, “The hybrid model is a valuable compromise: it enables fast shipping while still providing flexibility for complex orders”.

Pros and Cons of Cross Docking

Is cross docking really that effective? Like any strategy, cross docking offers significant advantages that can transform logistics operations, but it also comes with challenges that must be carefully evaluated.

Advantages

When implemented correctly, cross docking can optimize lead times, reduce costs, and improve the overall flow of goods.

- Reduced storage and handling time: cross docking minimizes the time goods spend in the warehouse, significantly shortening handling cycles. Products are received and immediately routed to shipping, bypassing traditional storage processes. This results in faster material flow and quicker distribution operations.

- Lower warehousing costs: since large inventories and complex storage systems are no longer required, companies can significantly reduce costs related to inventory management and goods handling.

- Better space utilization: eliminating long-term storage allows companies to optimize available warehouse space, resulting in leaner operations and increased capacity within the same footprint.

- Increased responsiveness: when supported by advanced systems such as WMS and TMS, cross docking enables companies to respond more quickly to orders, minimizing delays and improving customer satisfaction.

Disadvantages

Despite its benefits, cross docking is not suitable for every scenario and presents some limitations:

- Operational complexity: cross docking requires precise planning and flawless flow management, with tight synchronization between inbound receiving, sorting, and outbound shipping.

- Limited suitability for complex or customized orders: while highly effective for standardized, high-turnover orders, cross docking is less suitable for orders requiring complex or customized picking operations, where process flexibility is essential. The lack of flexibility in processes may limit its applicability to certain types of products or orders.

How WMS and TMS Support Cross Docking

“What is certain,” Nicola explains, “is that technology and automation play a crucial role in implementing cross docking correctly and achieving maximum efficiency. Inbound and outbound flows must be perfectly synchronized, which is why WMS (Warehouse Management System) and TMS (Transportation Management System) systems are essential.”

WMS – Warehouse Management System

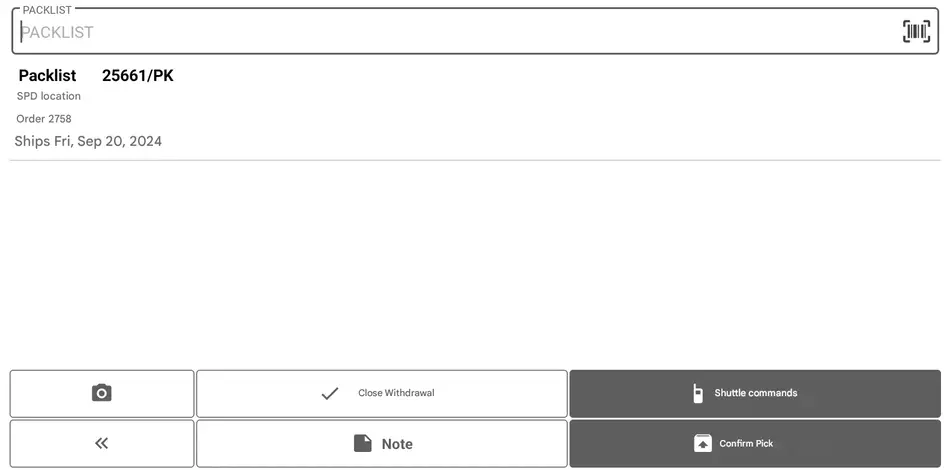

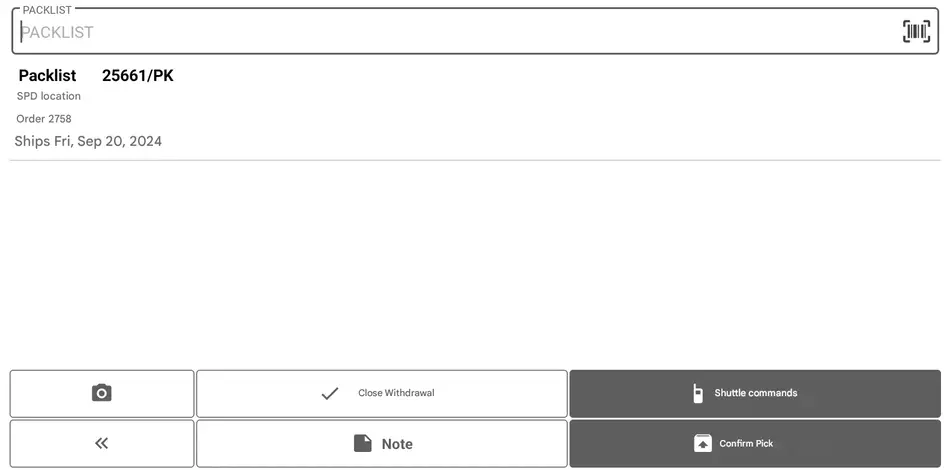

A WMS (such as silwa, Stesi’s WMS) is essential to ensure smooth cross docking operations. It enables real-time monitoring and tracking of every goods movement, optimizing the flow between receiving and shipping.

The WMS coordinates sorting operations, ensures correct transfers from inbound to outbound areas, and manages task prioritization.

“A well-implemented WMS,” Nicola concludes, “provides full visibility of goods and enables fast, informed decisions, ensuring total control over distribution center operations”. A WMS helps to:

- Reduce handling errors and misallocations.

- Increase sorting speed and shipment preparation efficiency.

- Automate operations using barcodes and RFID technologies.

TMS – Transportation Management System

A TMS manages transportation activities, coordinating vehicles and shipping schedules. A Transportation Management System enables companies to plan, organize, and optimize inbound and outbound transport routes while monitoring vehicle availability, traffic, and delivery times.

“The TMS is extremely useful for managing loading docks efficiently, avoiding congestion, and improving overall shipping performance,” Nicola explains. “Without transport visibility, cross docking becomes much harder to manage”. Key TMS benefits include:

- Optimized transportation costs and delivery times, reducing inefficient routes and optimizing loads.

- Improved capacity management and dock scheduling, ensuring that resources are allocated as efficiently as possible and that loading and unloading slot planning is optimized to avoid congestion.

- Real-time shipment visibility and tracking, allowing real-time monitoring of shipment status, with up-to-date data on arrival times and transport conditions.

WMS and TMS Integration

The true power of cross docking emerges when WMS and TMS are fully integrated. When these systems communicate seamlessly, inbound and outbound processes become perfectly synchronized. This integration allows companies to:

- Create a continuous, automated flow from receiving to shipping.

- Eliminate idle time through synchronized arrivals and departures.

- Reduce manual errors.

- Optimize resource utilization.

- Achieve end-to-end logistics visibility.

Industry Applications of Cross Docking

In which industries can cross docking really make a difference? The answer is simple: in all contexts where speed, flexibility, and resource optimization are crucial. Specifically:

- E-commerce: a sector where shipping speed is critical. Consumers expect short delivery times, sometimes even within 24 hours. In this context, cross docking significantly reduces storage and handling time by shipping products directly from inbound facilities to carriers, without passing through intermediate warehouses.

- Distribution and retail: among the main sectors that benefit from cross docking. Goods are received from suppliers and sorted for delivery to individual stores or distribution centers. By using cross docking, supply chains can reduce storage costs, speed up product distribution, and improve responsiveness to market demand.

- Make-to-order logistics: sectors such as automotive or manufacturing, where cross docking helps optimize the management of components required for production. When materials arrive, they are sent directly to production lines or assembly departments, reducing the time that would otherwise be spent in storage.

- Food and pharmaceutical industries: sectors where timeliness and traceability are essential. Cross docking enables the rapid sorting of fresh products, avoiding long periods in storage. This not only ensures that products reach retail outlets or distribution centers quickly, but also reduces the risk of spoilage, ensuring that goods are always in optimal condition for sale.

Other Logistics Models Beyond Cross Docking

While cross docking is one of the most effective solutions for reducing storage time and optimizing goods flow, other logistics models can be applied in parallel or in a complementary way, depending on specific business needs and the type of products handled. These include:

- Pick & Pack: one of the most traditional models, used when goods need to be picked from the warehouse and then packed for shipment. “This process is ideal for orders that require customization, such as special packaging, or when goods come from different warehouse locations,” Nicola explains. Unlike cross docking, which minimizes warehouse dwell time, Pick & Pack involves a certain level of storage and handling before shipment.

- Just-in-Time (JIT): a model focused on precision and timing, where goods arrive at the warehouse or point of sale exactly when needed, without any intermediate stock. However, Nicola points out that “while this approach significantly reduces storage costs, it requires flawless synchronization between suppliers and the distribution system”. Although JIT and cross docking both minimize storage, cross docking is a fast transit model, whereas JIT relies on flexible, demand-driven flow management, keeping inventory to a minimum at every stage.

- Third-party fulfillment (3PL): this model involves outsourcing logistics operations to an external provider that manages all stages, from inbound receiving and warehousing to final shipment. While 3PL allows companies to outsource and optimize logistics management, integrating it with cross docking can further accelerate operations, especially for high-turnover shipments. The result is a combined logistics approach that, as Nicola notes, “can be highly advantageous for companies that rely on specialized third parties to manage inventory but still want to speed up flows through cross docking”.

Cross Docking: The Key to Leaner Logistics

Cross docking is an ideal solution for companies seeking faster, more efficient, and leaner logistics operations, reducing storage time and optimizing flows. Supported by advanced digital systems such as WMS and TMS, cross docking enables companies to achieve maximum efficiency through continuous, automated goods handling.

The integration of these systems makes it possible to monitor, optimize, and track every stage of the logistics process, transforming the distribution center into a highly efficient transit hub. Want to learn more or explore software solutions dedicated to supply chain optimization? Contact us.

FAQ

What are the main advantages of cross-docking logistics?

Cross docking offers several logistics benefits, including reduced storage and handling time, which speeds up goods flow. It also helps optimize warehousing costs and improve space utilization within logistics facilities, reducing the need to build up inventory. It is a highly valued model because it increases responsiveness to market demand and improves customer satisfaction through faster shipments.

What are the differences between Cross Docking, Drop Shipping, and Direct Shipping?

In drop shipping, orders are shipped directly from the supplier to the customer, without passing through the seller’s warehouse. In direct shipping, the supplier sends goods straight to the end customer, bypassing any intermediate logistics center. In contrast, with cross docking, goods physically pass through a distribution center, where they are sorted and immediately shipped to their final destination, still involving an intermediate transit point.

Are Cross Docking and Transloading the same thing?

No. Transloading refers to changing the mode of transportation (for example, from rail to truck). Cross docking, on the other hand, focuses on the rapid sorting of goods (generally without changing transport mode) with the goal of minimizing storage time.

How does it differ from traditional warehousing?

In traditional warehousing, goods are stored for a certain period before being shipped. Cross docking, by contrast, reduces or eliminates this storage phase, increasing speed and lowering operating costs, as goods are immediately sorted for final shipment without long-term storage.

What technologies are required to implement cross docking effectively?

To successfully implement cross docking, companies need advanced technologies such as WMS (Warehouse Management Systems) and TMS (Transportation Management Systems). These tools ensure synchronized management of inbound and outbound goods flows. The WMS provides real-time inventory visibility, while the TMS optimizes transport routes and delivery times, improving overall operational efficiency.