Load Units play a crucial role in efficient warehouse logistics management. Without load units, each department would handle goods using different measurement units with varying weight and size (items, pallets, cartons, etc.), move individual pieces with multiplied handling operations, use storage space inefficiently, and track inventory without a standardized method. These logistical operating units provide standardization, traceability, handling efficiency, and safety.

In this article, Alessandro Riccio, Software Developer at Stesi specializing in warehouse logistics, explains the definition, meaning, types, and benefits of load unit, offering useful insights for both supply chain professionals and companies aiming to optimize their logistics operations.

Load Unit: definition and meaning

In logistics, a load unit is a standardized grouping of goods assembled on a support (e.g. a pallet) and managed as a single entity to facilitate handling, storage, and transportation. This is a fundamental supply chain concept because it improves organization and efficiency across warehousing, transport, and distribution activities. In practice, load units can take different forms, such as pallets, boxes, or containers.

Thinking in terms of load units allows operators to move an entire pallet with a single loading/unloading operation instead of manually handling dozens of cartons. Likewise, storing a load unit in a specific warehouse location means managing it as a single object, simplifying inventory control and traceability.

“From an information system perspective,” explains Alessandro Riccio, “load units in WMS software (Warehouse Management Systems) do not represent fixed locations defined during warehouse mapping, but rather mobile containers, such as boxes, bins, silos, or most commonly different types of pallets”. Just like warehouse locations, each load unit must be tracked by a unique identification code, its contents, its availability status, and its current storage location.

Types of Load Units

Classification by Type

Load units can be classified based on the type of goods, handling systems, and transport modes. The main categories include:

- Palletized load units, such as standard pallets, pallet boxes, or pallet cages;

- Containerized load units, such as ISO containers and swap bodies;

- Reusable logistics containers, such as bins, crates, or metal containers;

- Non-palletized load units, such as coils, drums, or big bags handled as single entities.

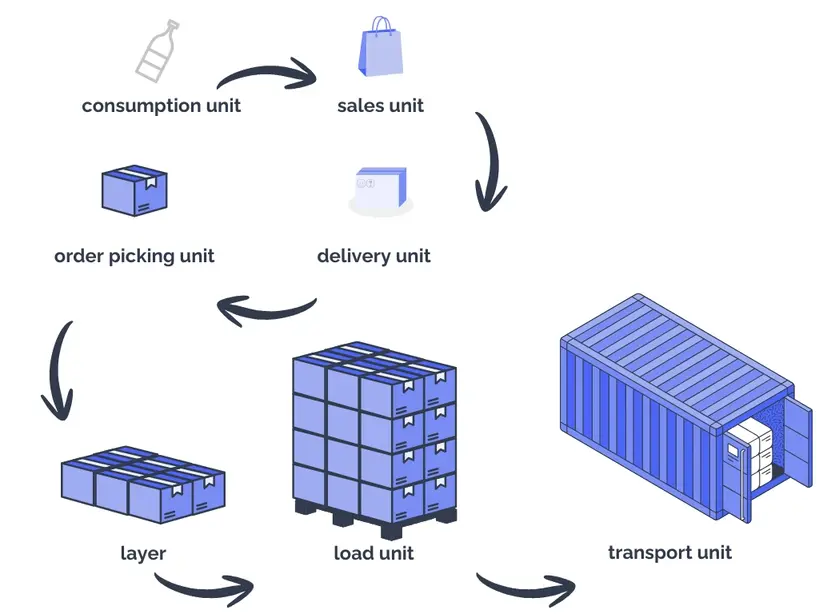

Classification by Levels

In logistics, load units are also classified by aggregation levels:

- First-level load unit: the smallest logistical unit, typically consisting of cartons stacked on a pallet.

- Second-level load unit: a grouping of multiple first-level units (e.g. several pallets bundled together or loaded into a container).

- Third-level load unit: an aggregation of multiple second-level units, often handled as a single entity in intermodal transport or large distribution centers.

Regardless of their classification, logistic load units’ core principle remains the same: transforming multiple products into one manageable logistical entity across the entire supply chain.

Benefits of Load Units

Managing goods through load units transforms multiple products into a single logistics entity, simplifying operational management throughout the supply chain. In warehouses, moving a full pallet with a forklift is faster and more efficient than handling individual cartons. In transport, standardized pallets and containers improve loading efficiency and space utilization. The main benefits include:

- greater standardization, enabling simplified management of clearly identifiable logistical entities;

- automation support, since automated and semi-automated systems (AS/RS, AGVs, sorters) operate on uniform and predictable loads;

- higher operational efficiency, by reducing the number of handling operations (one pallet instead of dozens of boxes);

- better space utilization, both in storage and transport;

- simplified traceability, since each load unit can be associated with a location, an order, or a batch/lot.

Load Units in the warehouse: how to identify them with unique codes

“In WMS software (such as our silwa), warehouse load units can be identified using different types of codes,” explains Alessandro:

- internal unique codes generated by the WMS or based on custom plant rules, suitable for internal handling or outbound pallets not requiring customer-readable labels;

- GS1-compliant codes, used for standardized identification.

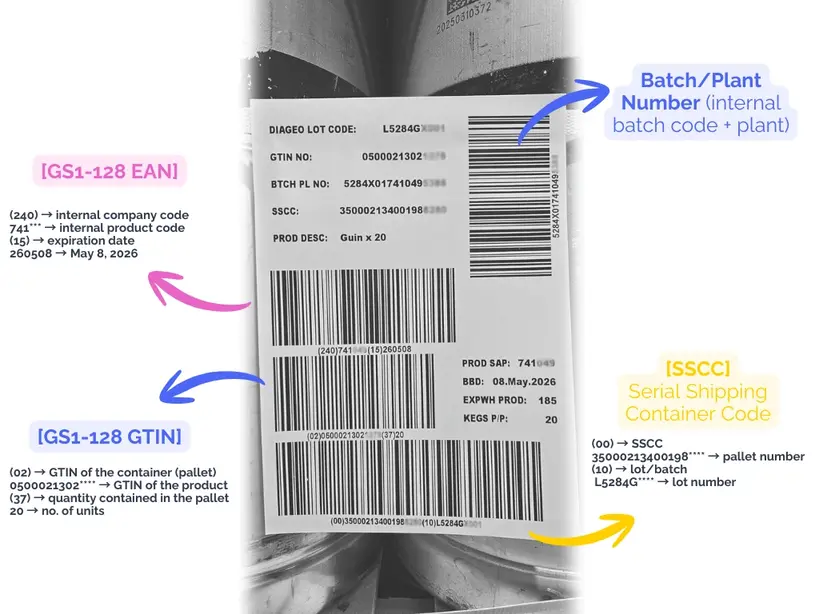

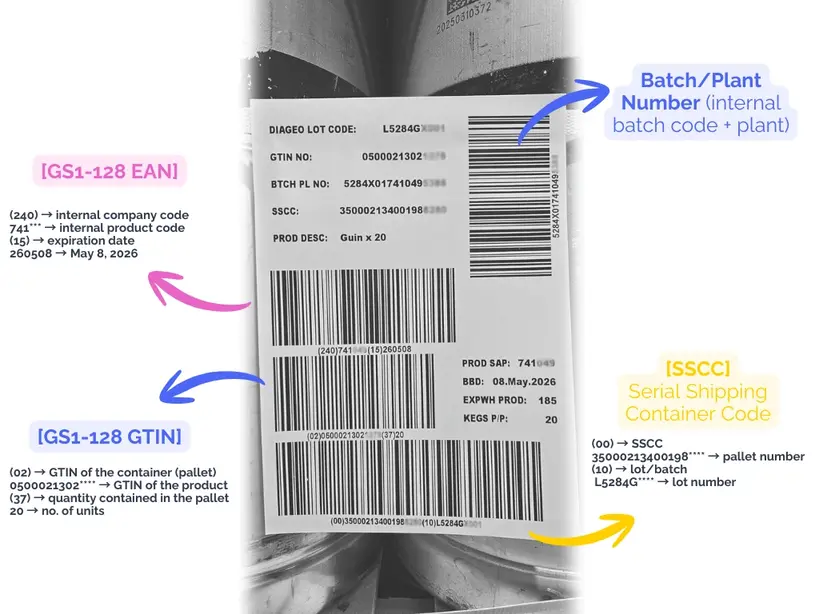

What Is the GS1 Standard? “GS1 codes (EAN, GTIN, etc.) are international standards defining shared rules for identifying products, pallets, and logistics units using unique barcodes across different companies.” explains our Software Developer. A GS1 barcode may contain:

- the SSCC (Serial Shipping Container Code) identifying the load unit though the entire supply chain (18 digits);

- the product code contained inside;

- the batch/lot code (alphanumeric code);

- the expiration date;

- and other standardized data elements.

“The use of barcodes brings several advantages, including a significant increase in operational speed”. By scanning the code applied to a logistic load unit with a handheld terminal, operators can instantly retrieve its contents, verify whether the material has been assigned to a shipment, and use the load unit in any of the processes involved (picking, storage, packing). In the image above, you can see a logistics label with multiple GS1 barcodes, each associated with its own prefix (Application Identifier), identifying the product, batch, quantity, and the logistic unit via the SSCC. To learn more, refer to this guide on GS1 codes (EAN, GTIN) and SSCC.

“The fact that our WMS can interpret these barcodes allows us to read all the information with a single scan” explains Alessandro Riccio. “Let’s assume we need to receive a pallet that has just been delivered: if the supplier has applied a GS1 label containing all the required data, the operator can scan it in silwa’s goods receiving function and the fields for load unit, item, batch and expiry date will be filled in automatically”.

Creating a new Load Unit

Logistic load units can be created in the WMS in two main ways.

The first method consists of creating the load unit directly within the WMS, typically during warehouse operations. For example, when an operator performs order picking and places the goods onto a pallet, they can request the creation of a new logistic load unit directly from the picking function. The WMS automatically assigns an identification code and triggers label printing, allowing the operator to immediately proceed with subsequent activities. The same mechanism applies to all operational functions that involve the use of a load unit.

The second method involves importing load units from external systems, such as ERP, MES, or other integrated software. In this case, the WMS receives not only the load unit ID, but also all associated content and attribute data. This workflow is particularly relevant in scenarios where the WMS manages the handling and shipment of internally produced pallets, ensuring informational continuity between production and logistics.

Managing Load Units in production and warehousing: the Alpla case study

Thanks to the complete availability of this data, the WMS can autonomously manage operational complexity, providing operators with precise and timely instructions through the FGS function (Forklift Guidance System). This functionality guides operators step by step during mission execution: on the terminal (tablet) mounted on their handling vehicle, clear instructions are displayed for each task (for example: “pick pallet X from location A and move it to location B”), ensuring that warehouse load units are handled in compliance with customer logistics rules and enabling immediate decision-making even in high-throughput production environments.

Defining Load Units to improve logistics efficiency

The way load units are defined depends on warehouse operating logic and each company’s specific processes. Establishing what constitutes a load unit, how it is identified, and how it is moved is a strategic decision that must be made in advance, based on storage, production, and shipping requirements.

For this reason, there is no one-size-fits-all configuration: proper load unit modeling is the first step toward making systems such as WMS (Warehouse Management System), MES (Manufacturing Execution System), and FGS (Forklift Guidance System) truly effective. If you are unsure where to start or want to validate the consistency of your logistics model, let’s talk. We offer targeted consulting to define the most suitable logic and processes for your organization.

FAQ

What is a warehouse load unit?

A Logistic Load Unit is a standardized grouping of goods, created and managed as a single entity to simplify storage, picking, and material handling operations within the warehouse.

Is a load unit always handled manually?

No, a load unit can be handled manually or by mechanical and automated equipment, such as forklifts, stacker cranes, AGVs, or robotic systems.

Can a container be considered a load unit?

A container is more commonly considered a transport unit (or Intermodal Transport Unit – ITU), which may contain one or more warehouse load units.

What is the difference between a load unit and a transport unit?

Load units are groupings of goods on pallets or in boxes designed for efficient handling and storage. Transport units (ITU) are standardized containers for intermodal transport (containers, swap bodies, semi-trailers, etc.) that move across different modes of transport. Multiple load units can form a single transport unit.