Logistics companies face the daily challenge of managing complex shipments and multiple carriers, dealing with issues related to delivery visibility, label generation errors, and documentation handling. All of these obstacles can significantly slow down operations and quickly impact costs. For example, when parcel labels are not generated in-house, the task is delegated to carriers, who then charge for the service. So how can warehouse and shipping operations be optimized? The answer is simple: with Stesi’s Carrier Interface, which enables companies to streamline these processes, improve accuracy, reduce costs, and centralize shipment management on a single platform.

But what exactly is a Carrier Interface, and what real benefits does it bring to companies? We discussed this with Giuliano Fiorotto, Product Owner at Stesi.

What Is a Carrier Interface?

A Carrier Interface is a software interface that enables smooth, standardized, and centralized communication between company systems (from ERP and WMS to e-commerce platforms) and transport service providers, known as carriers.

This interface acts as a bridge, facilitating the flow of information at every stage of the shipping process, from label generation to parcel tracking during delivery. With such a solution, companies can avoid managing separate interfaces for each carrier, significantly reducing costs and simplifying operations. By minimizing manual intervention, the Carrier Interface improves both accuracy and operational efficiency, allowing businesses to handle large shipment volumes with minimal effort.

Why companies can no longer do without a Carrier Interface

Adopting a Carrier Interface provides numerous advantages:

- Centralized shipping operations: by standardizing communications, the Carrier Interface enables unified and centralized shipment management. This reduces the number of required interfaces, eliminating complexity and the costs associated with multiple carrier connections.

- Advanced shipment tracking: a Carrier Interface allows real-time monitoring of delivery status, improving visibility and logistics planning. Tracking data can be exported to other systems (such as ERP, e-commerce platforms, for example, the “track your order” page, or physical stores) and used to generate KPIs that measure carrier performance, supporting data-driven decision-making.

- Simplified returns management: the Carrier supports not only outbound shipments but also return flows, making reverse logistics easier and improving the customer experience. This is particularly valuable in e-commerce, where returns represent a critical component of post-sales service.

- Automatic carrier selection: the Carrier can automatically select the most suitable carrier based on cost, destination, weight, volume, delivery time, and other configurable parameters. This enables companies to reduce costs and optimize logistics operations by choosing the best carrier for each shipment.

- Higher efficiency and fewer errors: a Carrier automates label generation and documentation management, reducing the risk of manual errors. It can also automatically correct incomplete or incorrect input data, such as invalid addresses, preventing delays and improving delivery accuracy.

Key features of Stesi’s silwaCARRIER

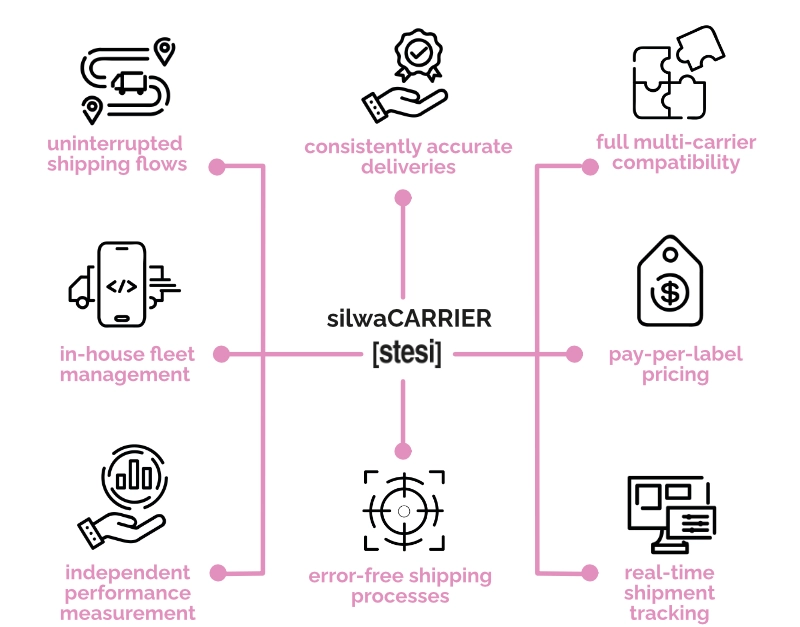

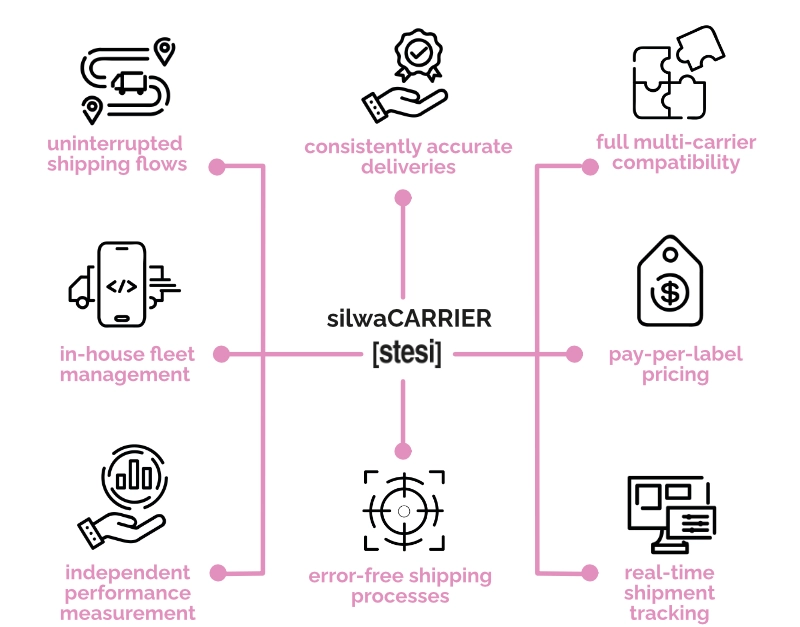

Stesi’s silwaCARRIER software is designed to simplify shipping management through advanced features tailored to modern business needs:

- Multi-carrier integration: with a single interface to the carrier layer, the system is already integrated with many transport providers and can be easily extended to additional carriers as business needs evolve. It also allows companies to view and configure potential new carriers, making shipping operations more flexible and less complex.

- Real-time shipment monitoring: through its tracking functionality, silwaCARRIER provides timely updates on shipment status. Information is continuously available, increasing transparency and ensuring a better customer experience. In addition, the interface offers a unified tracking page that does not display the carrier name, providing customers with a single, intuitive tracking interface.

- Automation of shipping operations: silwaCARRIER reduces manual workload by automating label generation and documentation handling, streamlining the entire shipping process. This eliminates repetitive tasks, accelerates operations, optimizes processing times, and drastically reduces error margins.

- Input data error correction: Stesi’s Carrier Interface can detect and correct shipping data errors, such as incomplete or inaccurate addresses. This reduces the risk of delays and delivery issues, ensuring data accuracy and smooth shipment execution.

- Elimination of fixed fees: with silwaCARRIER, companies pay only for each label actually printed, eliminating monthly fixed costs and optimizing expenses. The system also unifies label printing, preventing companies and carriers from managing separate labels and reducing the number of required printouts, resulting in significant cost savings.

- Carrier App integration: the interface is already integrated with Stesi’s Carrier App, enabling companies to manage their own fleets as well. Operators receive real-time updates on delivery processes, improving internal communication and ensuring more efficient resource management.

- Performance and KPIs: silwaCARRIER also functions as a performance analysis tool, providing KPIs that help monitor carrier service quality. This gives companies independent, objective data (separate from carrier reports) to evaluate delivery effectiveness and optimize strategic logistics decisions.

- Accessibility and customization: the system is designed to suit businesses of all sizes, from small enterprises to large corporations. In addition to being cost-effective compared to other market solutions, it is comprehensive, flexible, and highly customizable, making it suitable for industries ranging from retail to manufacturing.

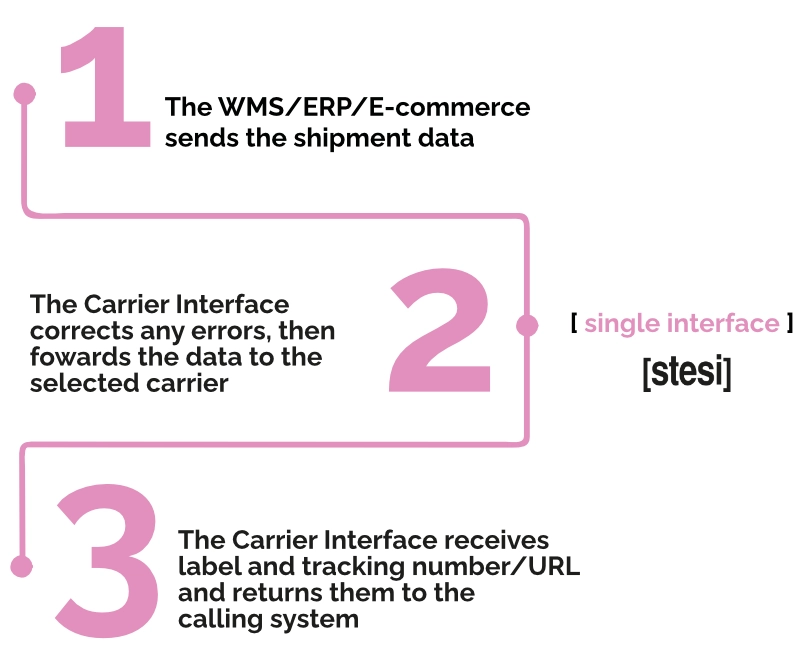

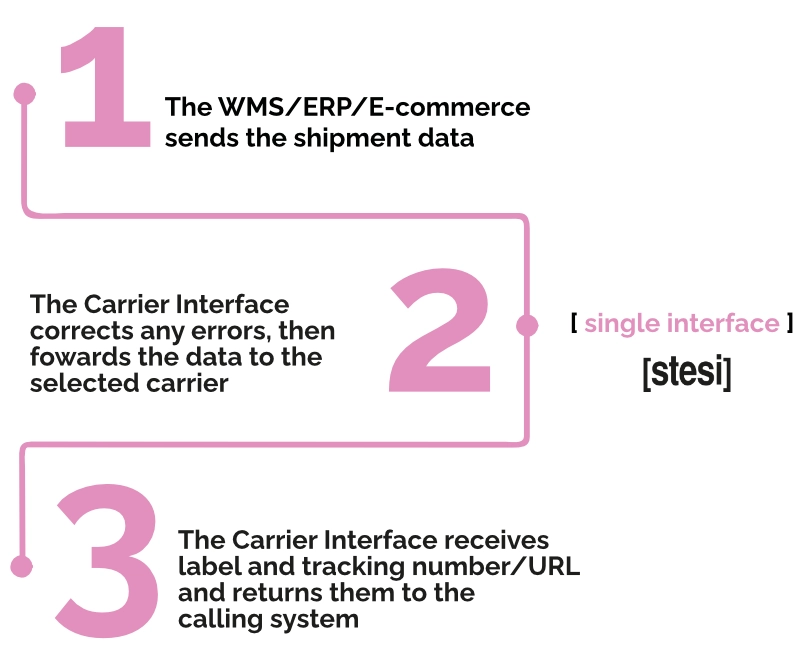

How a Carrier Interface works

Stesi’s Carrier Interface is designed to be simple and intuitive. Once configured with the various carriers, companies can manage shipments automatically and receive real-time status updates. The result is a streamlined information flow, faster response times, and more accurate, timely communication with customers. The process consists of three main phases:

- Data transmission: the company’s management system (WMS, ERP, or e-commerce platform) sends shipment data to the Carrier Interface through a unified interface.

- Validation and forwarding: the Carrier Interface validates the data, automatically correcting any errors (such as incomplete or incorrect addresses), and then forwards the information to the selected carrier via its standard interface.

- Tracking data reception: the Carrier Interface receives tracking information from the carrier, such as the tracking number or monitoring URL, and sends it back to the company system through the unified interface.

Business benefits from a Carrier Interface

Implementing a Carrier Interface delivers significant business advantages by improving operational efficiency and reducing costs:

- Time savings and lower operating costs: developing a single interface to the Carrier Interface, rather than maintaining separate connections for each carrier, dramatically reduces integration costs. By automating shipping processes, companies optimize processing time and reduce overall operating expenses.

- Higher accuracy and fewer shipping errors: automation minimizes errors in shipment handling, resulting in more precise operations and more reliable deliveries, increasing customer satisfaction.

- Optimized delivery times and improved customer satisfaction: an efficient, centralized management system optimizes delivery lead times and ensures high service quality. Customers benefit from a smoother purchasing experience and on-time deliveries, key factors in building trust and loyalty.

How to implement a Carrier Interface

Implementing a Carrier Interface is quick and straightforward. Thanks to its modular architecture, it integrates easily with existing enterprise systems, enabling a smooth transition. Steps to follow:

- Contact a company specialized in logistics software solutions, ideally also acting as a system integrator.

- Request an initial (free) consultation to identify specific challenges and industry requirements.

- Request a demo.

- Launch the project, including integration with existing enterprise systems where applicable.

- Start benefiting from the software, from resource savings to increased customer satisfaction.

Not sure where to start? Contact us and let’s define the first steps together.

Carriers already integrated into silwaCARRIER

As described in this article, silwaCARRIER is a software solution that can integrate with any carrier and allows new configurable carriers to be added. To eliminate setup time and costs, Stesi has preconfigured connections with a wide range of international and local carriers. These include:

Palletways

SDA Poste Italiane

Susa Trasporti Spedizioni

TNT (will become FedEx)

Europa Trasporti

UPS

ARCO Spedizioni

Barone Trasporti

Bracchi Transport & Logistic

BRT

Ceccarelli Group

De Deorgio Group

DHL

Fercam Logistics & Transport

GLS Corriere Espresso

Gruppo Zingali

IGS Logistics Group

Trading Post Express Service

Tardini Logistica Spedizioni

Contact us to learn more.