Optimizing picking routes is becoming an increasingly critical factor in warehouse management and logistics as a whole.

But what does it actually mean? “Warehouse picking route optimization” refers to the set of strategies, processes, and rules aimed at maximizing the efficiency of order picking operations performed by warehouse operators. This practice is essential to fulfill outbound orders quickly and accurately and to ensure that the right materials are made available for production and processing in a timely and efficient manner. Improving picking routes through well-defined strategies is crucial to significantly reduce travel distances and execution time, leading to higher productivity and substantial cost savings. The definition of picking paths plays a key role in achieving two objectives: on the one hand, ensuring complete and accurate order fulfillment while minimizing travel time and distance; on the other, reducing the risk of accidents by organizing vehicle movements so that multiple handling equipment do not converge in the same warehouse areas.

To better understand how picking route optimization works, we spoke with Elisa Modolo, Software Developer at Stesi, who explained the preliminary steps and variables that must be considered in order to improve picking operations effectively.

How to optimize picking routes: preliminary phases

“In order to calculate the most efficient picking route,” Elisa explains, “at Stesi we adopt a comprehensive approach that takes multiple factors into account from the very early design stages.” In particular, it is important to consider:

Optimal stock allocation

It is essential to organize inventory in the most effective way, taking into account warehouse layout and the specific operational needs of each customer. For example:

-

by using the item turnover rate, “which can be easily calculated with a tool provided by Stesi,” Elisa adds, to position fast-moving SKUs closer to packing stations, thus reducing picking time. “Conversely, given the slower opening times of mobile racking systems, we recommend storing slow-moving items there, for both operational efficiency and ease of picking”;

-

by storing goods in bulk storage areas or floor stacks in a homogeneous way, i.e. by item code or lot. “Placing too many different SKUs in locations where access and identification are not immediate can significantly complicate picking operations”.

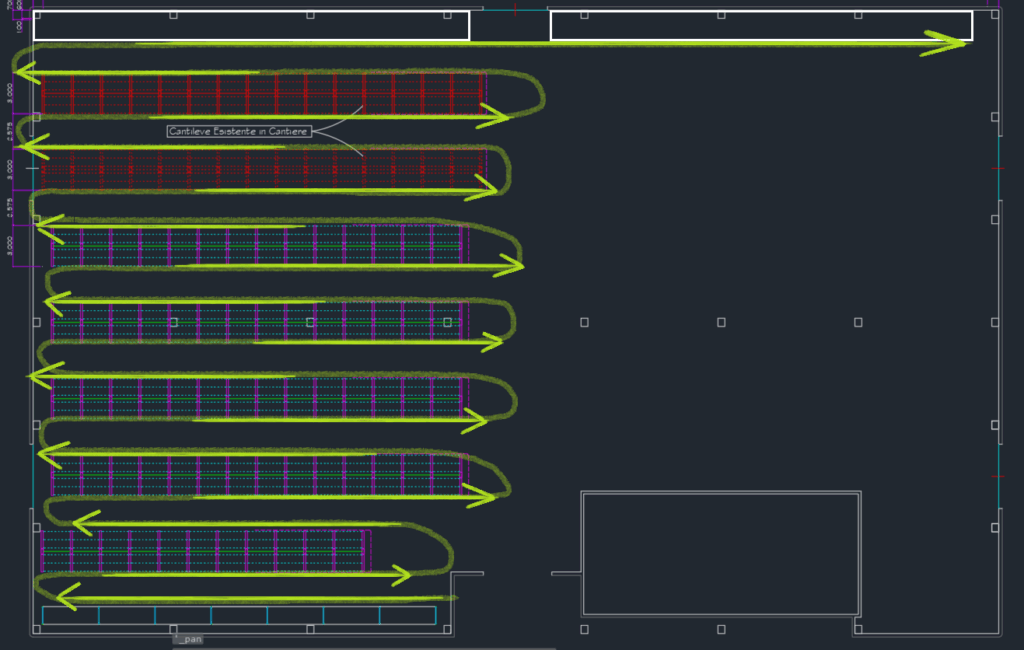

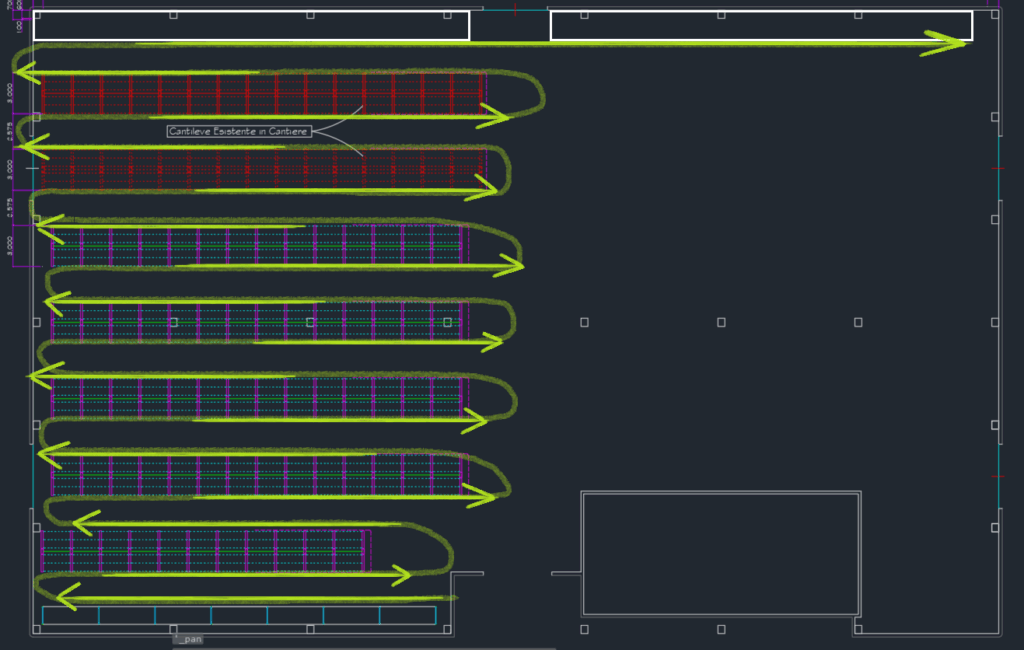

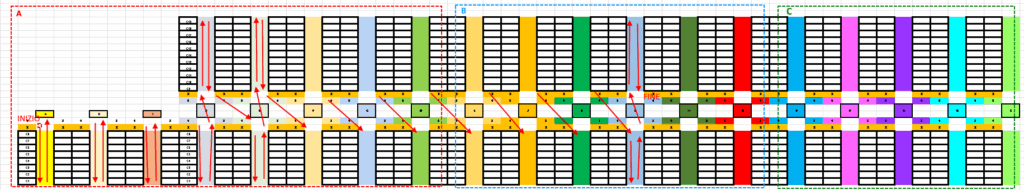

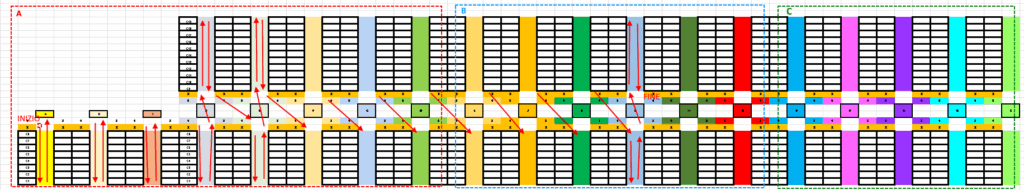

layout of a possible picking path between rack aisles

Type of picking equipment used in the warehouse

Understanding which material handling equipment is used for picking is crucial when defining an optimization strategy. For warehouses relying mainly on manual picking, optimization requires placing goods in easily reachable locations and avoiding excessively high rack levels.

For operations using man-up forklifts or order pickers, optimization takes into account the ability to perform picking at height, fully exploiting vertical storage capacity, unlike operations using standard forklifts, where pallets must be brought down to floor level for each pick. “In short,” Elisa explains “the equipment available in the warehouse makes a major difference when it comes to picking optimization. That’s why these aspects must be addressed during the early design phase.”

Shipment volumes

“Depending on a customer’s typical shipping volumes, different strategies can be adopted,” Elisa notes. One example is batch picking, a common strategy in e-commerce environments, which consists of grouping multiple orders into a single picking run and is ideal for high picking frequency operations.

“In other situations,” Elisa continues, “picking optimization may require a different approach, such as splitting picking activities across multiple zones or facilities. This is typical for companies with several warehouses or picking areas, where an order may need to be fulfilled simultaneously from different locations.”

These approaches can also be combined. “For some of Stesi’s customers in the food industry, we have integrated shipment consolidation by destination with differentiated picking flows, taking into account different product categories such as ambient, refrigerated, and frozen goods”.

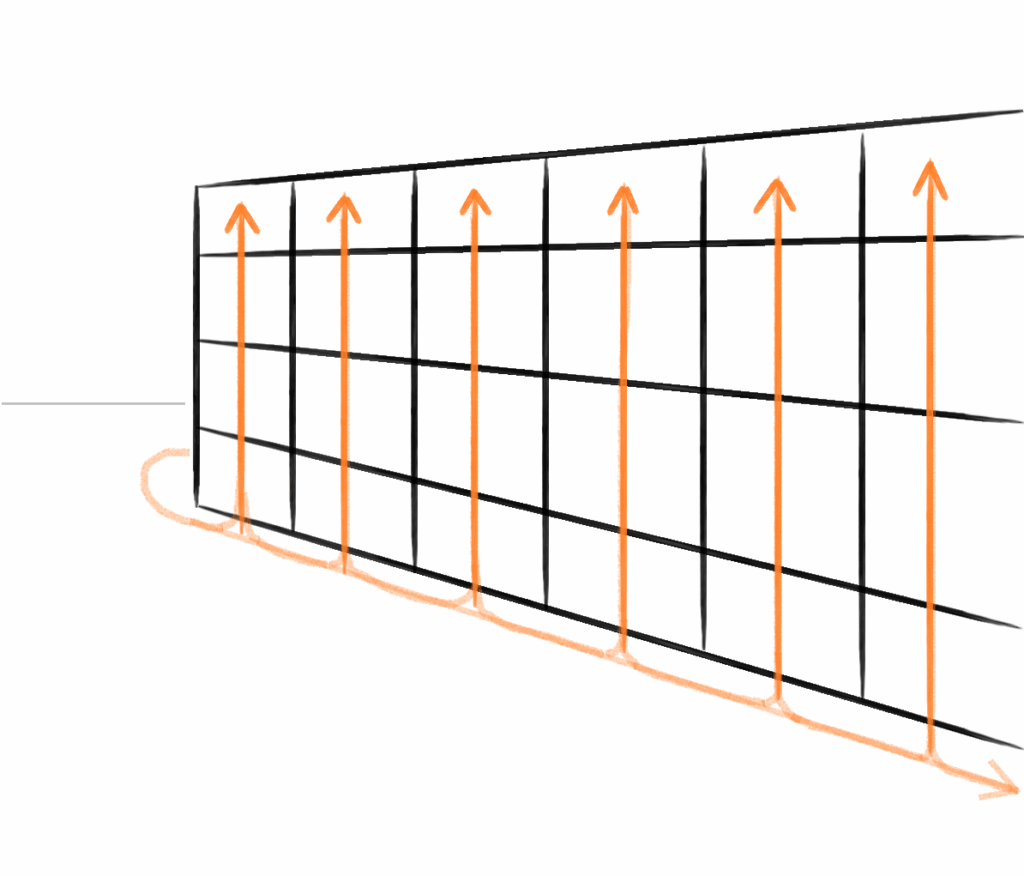

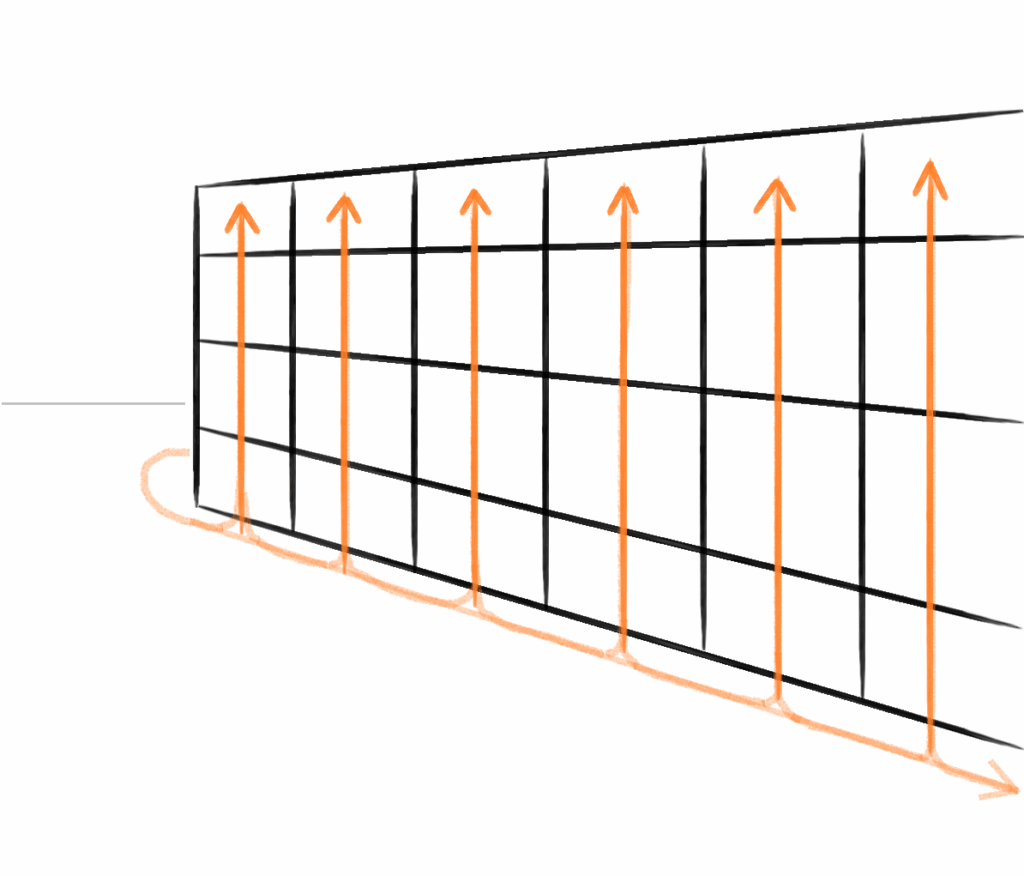

vertical picking sequence along rack bays

Additional considerations

When determining the optimal picking route, other variables must also be taken into account:

-

weight and fragility of items: fragile goods should be picked last so they can be placed on top of other items, while heavy goods should be picked first;

-

FEFO logic (First Expired, First Out): typical in the food industry, where items with the earliest expiration date must be picked first to avoid waste;

-

additional expiration date checks: to track the expiration dates of products already shipped to each customer, ensuring that newly picked goods always have later expiration dates.

proposed picking route in a warehouse with two opposing rack blocks

Optimizing picking with silwa

To further optimize operations, silwa also offers mission dispatching modules, which efficiently distribute tasks across operators and handling equipment in different warehouse areas. This allocation not only improves picking lead times but also enhances safety by preventing excessive concentration of vehicles in a single zone.

Would you like to learn more about silwa and understand the concrete benefits it can bring to the optimization of picking operations in your warehouse? Contact us.