Every year, during peak periods such as Black Friday, the Christmas season or seasonal sales, warehouses turn into true operational hubs. Demand increases, lead times shrink and efficiency becomes the key to maintaining control over increasingly complex flows.

Managing warehouse seasonality means dealing with a delicate balance: ensuring speed and accuracy even when volumes grow, resources become constrained and delivery pressure reaches its highest levels. These are precisely the moments when logistics proves how ready it is to respond to market changes.

In recent years, the adoption of technologies such as Warehouse Management Systems (WMS), automation and predictive algorithms has enabled increasingly proactive planning. Today, the challenge is no longer just managing peaks, but anticipating them and transforming them into a competitive advantage for the entire supply chain.

We explored this topic with Elisa Modolo, Software Developer at Stesi, who explained how seasonal logistics can be efficiently managed through advanced digital tools and well-structured processes.

What does ‘warehouse seasonality’ mean

Warehouse seasonality refers to cyclical and predictable variations in product and service demand that occur throughout the year. It affects many different industries (from food to electronics, from fashion to pharmaceuticals) and stems from consumer habits linked to holidays, seasons and market trends.

As Elisa explains, seasonality can be viewed from two perspectives: “On one hand, there is physiological seasonality, linked to times of the year when certain products experience higher demand, such as sweets at Christmas or air conditioners in summer. On the other, there are extraordinary peaks, such as Black Friday or promotional campaigns, which concentrate in just a few days volumes that would normally be spread over several weeks”.

In both cases, logistics must handle a sudden increase in activity: more inbound and outbound goods, shorter order fulfillment times, possible use of temporary staff and a higher risk of operational errors. The ability to maintain balance between flows, resources and space therefore becomes a key indicator of warehouse efficiency.

In recent years, seasonality has also become more dynamic and less predictable. Quasi-seasonal events such as back-to-school, Prime Day or flash promotions require even more flexible planning. Today, the real differentiator is the ability to read real-time data and adapt quickly.

The main challenges of seasonal logistics

When volumes increase suddenly, the warehouse becomes a system under pressure. High inbound volumes, accelerated order fulfillment and a surge in shipments put every department’s coordination to the test. Critical issues mainly emerge in four areas: space, resources, processes and time.

Among the most common challenges are:

- Increased volumes to handle, which may cause congestion in storage areas and slow down picking operations;

- The need for seasonal workforce, with the resulting risk of errors due to limited training or partial knowledge of operational workflows;

- Pressure on delivery lead times, requiring minimal margins for error and optimization of every process phase;

- Complexity in priority management, especially in omnichannel logistics, where orders originate from multiple channels and platforms;

- Higher risk of unexpected events and inefficiencies caused by demand variability or poor cross-department coordination.

Beyond technical aspects, there is also a strong human factor affecting operational performance. During seasonal peaks, workload intensity can generate stress, reduced concentration and an increase in manual errors.

“During peak periods, even the simplest operations become critical,” explains Elisa. “What makes the difference is preparation and the ability to make fast decisions based on up-to-date data. Those who manage to do this turn peak periods into an opportunity to improve the entire organization.”

From reaction to prediction: how seasonal management has evolved

Over the past decade, warehouse seasonality management has shifted from a reactive approach to an increasingly strategic one. In the past, demand peaks were handled by increasing staff or building up inventory. Today, the logistics objective is to anticipate fluctuations and plan resources, space and operational priorities in advance.

Technology has made this shift possible.

The introduction of WMS solutions, combined with automation and data analytics, has significantly improved forecasting capabilities. “Today, the real difference lies in data and in the ability to anticipate demand: planning no longer means just reacting, but predicting,” explains Elisa Modolo.

The most significant evolution concerns the use of Big Data and predictive algorithms, which analyze historical trends and help identify peak periods well in advance. Forecasting models based on historical data, increasingly adopted in logistics, enable efficient peak management by optimizing item rotation, reducing stock levels and improving overall service levels. For example, many Stesi customers use a dedicated dashboard for calculating item turnover rates based on ABC classification, which helps optimize product slotting and replenishment planning starting from historical data analysis.

“Today,” says Elisa, “thanks to WMS solutions like Stesi’s silwa, it is possible to forecast demand trends with a level of accuracy that was unthinkable just a few years ago. This enables proactive workforce planning, warehouse preparation and precise resource allocation.”

The result is a more data-driven logistics operation, capable of responding quickly to market fluctuations and turning periods of high complexity into a long-term competitive advantage.

How the silwa WMS supports seasonal warehouse management

Handling seasonal peaks requires management systems that can adapt quickly and accurately, ensuring operational continuity even when volumes increase. This is precisely where silwa, Stesi’s WMS, provides decisive support in warehouse planning and process control.

Designed to be modular, scalable and fully integrable with other enterprise systems, silwa enables precise management of changing workloads and rhythms typical of seasonal peaks.

Its strength lies in combining planning, automation and data analytics, turning demand variability into a controlled and measurable process.

Scalability and modularity

One of silwa’s key strengths is its ability to adapt to the volume and complexity variations typical of seasonality. During peak periods, a rigid system risks slowing down the entire operational chain, while a modular structure allows targeted intervention without disrupting ongoing activities.

The scalability of the WMS ensures continuity both during growth phases and during normalization of flows. In practice, functions can be expanded or reduced according to volume, while maintaining stability and control.

“silwa is designed to adapt,” explains Elisa. “It grows with customer volumes and needs, maintaining control even at maximum pressure. This approach allows flexible responses to market changes without sacrificing efficiency”.

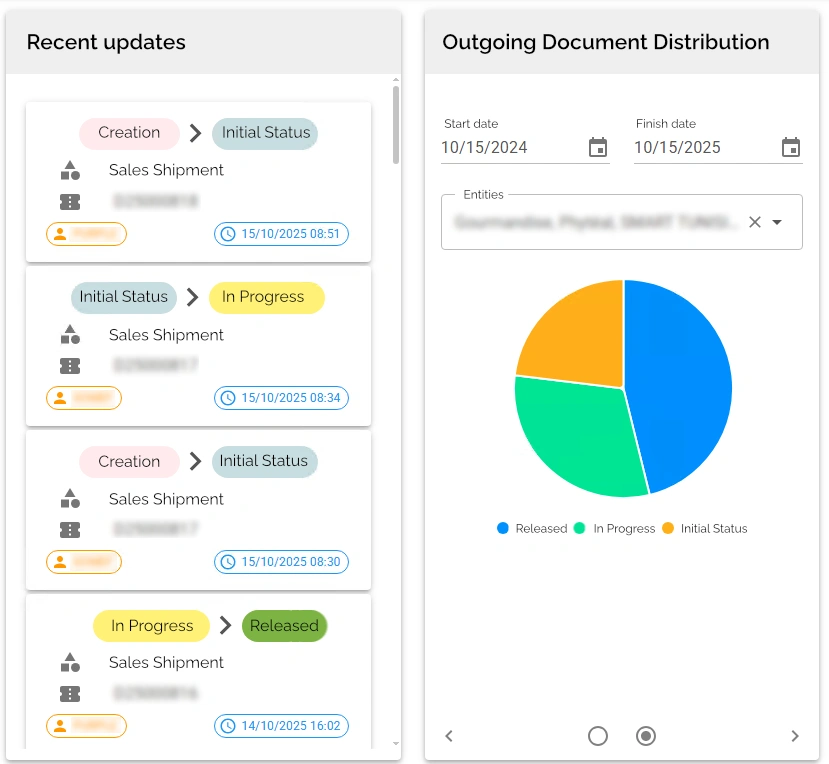

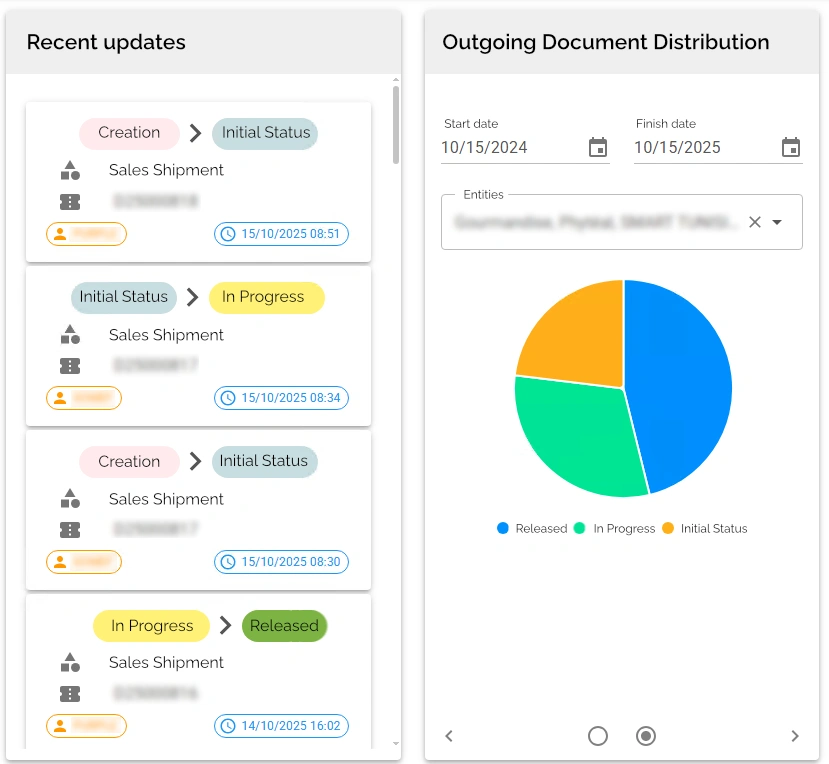

Real-time monitoring and KPIs

During seasonal peaks, process control is essential to maintain stability and business continuity. That is why silwa provides constantly updated dashboards and performance indicators, enabling real-time monitoring of warehouse activities.

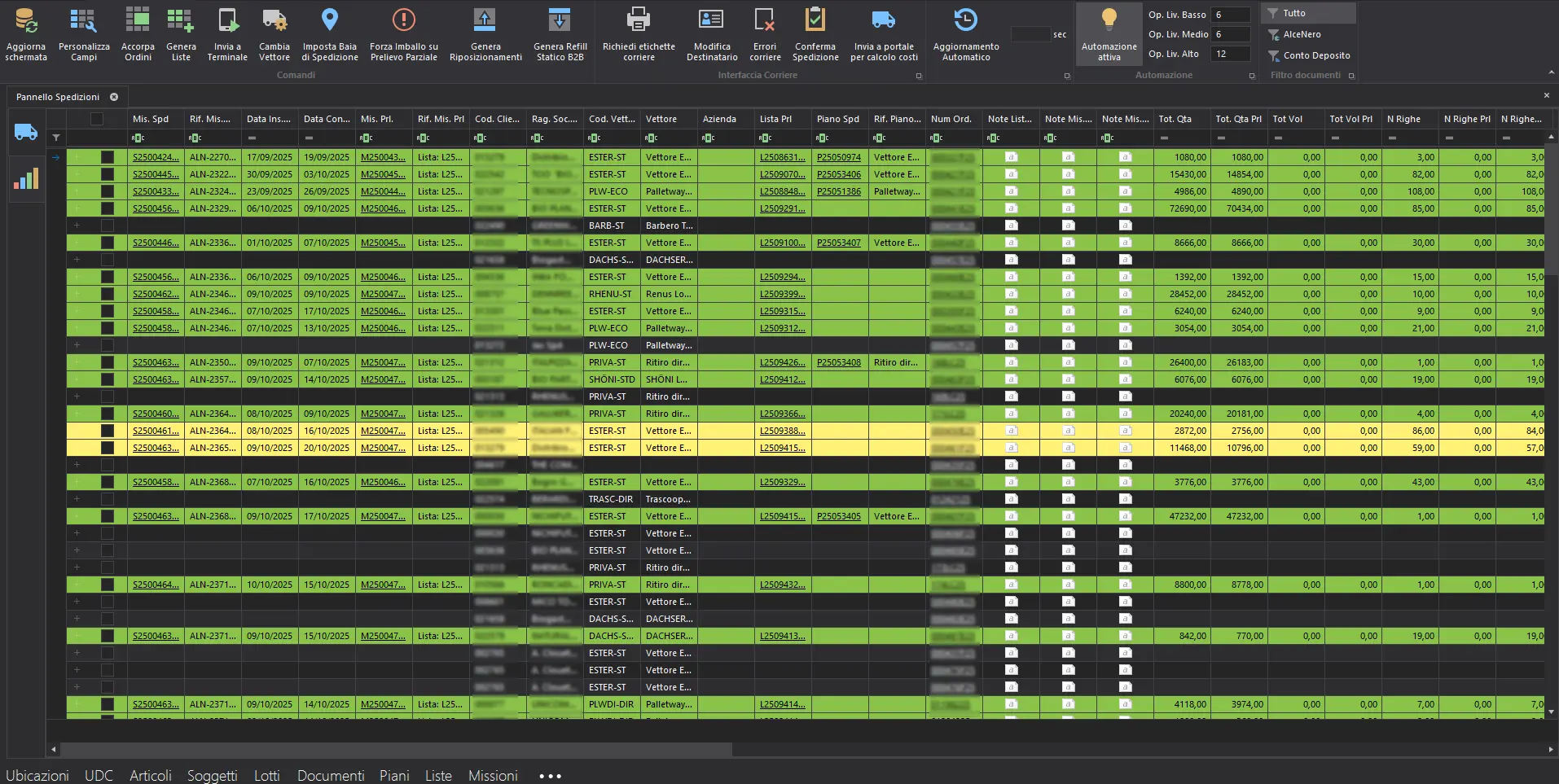

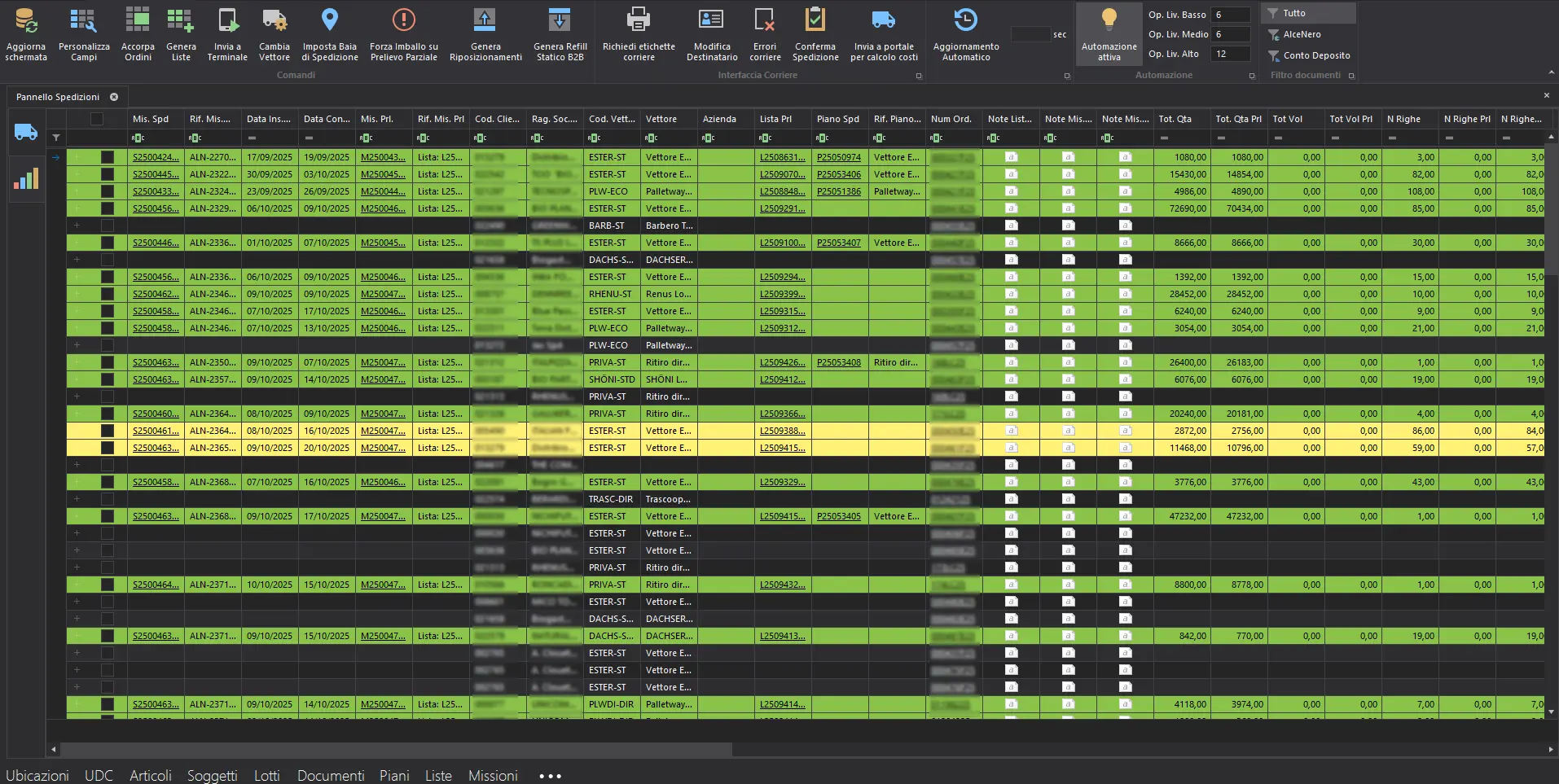

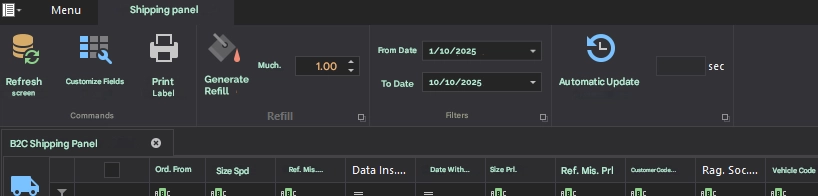

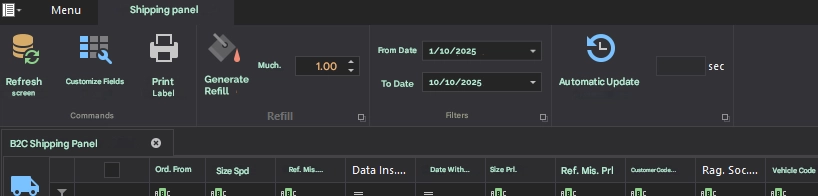

With a complete overview of orders, shipments and operator performance, the system allows rapid identification of bottlenecks and the implementation of targeted corrective actions. In particular, the Shipping panel enables step-by-step order fulfillment tracking, priority assignment and mission management based on urgency and complexity.

Continuous data control helps balance speed and accuracy, reducing errors and ensuring that every shipment meets defined quality standards.

Historical data analysis and forecasting

Long-term volume forecasting is what makes it possible to turn seasonality into a competitive advantage. By analyzing historical data, a WMS such as silwa can identify trends, estimate future demand and proactively plan required resources.

This predictive capability leads to more efficient warehouse organization: from reorganizing picking areas to optimizing picking paths and pre-allocating resources. In some projects, such as the one developed for Alce Nero, a company specializing in organic food products, the system automatically calculates eCommerce demand based on past data and generates refills or relocations, minimizing waste and downtime.

“Historical data tells much more than it seems. Analyzing it allows you to anticipate needs and prepare the warehouse well in advance, making operations more stable and accurate even during demand peaks.” says Elisa.

Automation and dispatching

During peak periods, execution speed must coexist with quality and operational accuracy. For this reason, managing seasonal staff becomes a strategic logistics component.

Through intuitive interfaces and guided workflows, silwa allows even temporary operators to work efficiently within the warehouse, reducing training time and minimizing errors. The goal is to enable every resource to operate autonomously and in coordination, even under maximum pressure.

Process automation further supports this flexibility, especially in critical areas such as task assignment and shipment prioritization. The silwa dispatching module automatically distributes tasks based on operator skills and task complexity, ensuring workload balance and optimal use of available competencies.

Finally, integration with eCommerce platforms and carriers completes the process: thanks to the Carrier Interface, the WMS automatically manages shipping labels and shipment data, ensuring a smooth, synchronized and fully controlled logistics flow.

Managing warehouse seasonality: an opportunity for growth

Every seasonal peak is also a learning opportunity. In warehouses, high-activity periods test the ability to plan, coordinate and respond quickly, but they also provide a chance to refine processes and consolidate operational best practices.

When flow management is supported by digital tools, seasonality becomes a training ground for efficiency, ideal for testing strategies, optimizing resources and improving collaboration between teams and technologies.

“Managing seasonality well means turning complexity into efficiency,” notes Elisa. “It is the opportunity to understand how prepared logistics truly is for the future”.

Early preparation, data analysis and reliance on scalable solutions like silwa enable companies to face peaks with confidence, transforming periods of high pressure into lasting competitive advantage.

Do you have questions about managing seasonal peaks? Contact us to discover how silwa can support your logistics operations.